WJK Series - God Mabu Library (Fourth Floor)+ More

Our products apply to pre-weaving workshop section in the lines of textile industry the plant of warping、sizing and beaming. The weaving workshop section-the plant of weave, and the after-treatment workshop section-varies kinds of large packages of warp beam and batched roil for storage and turnover in the dyeing.

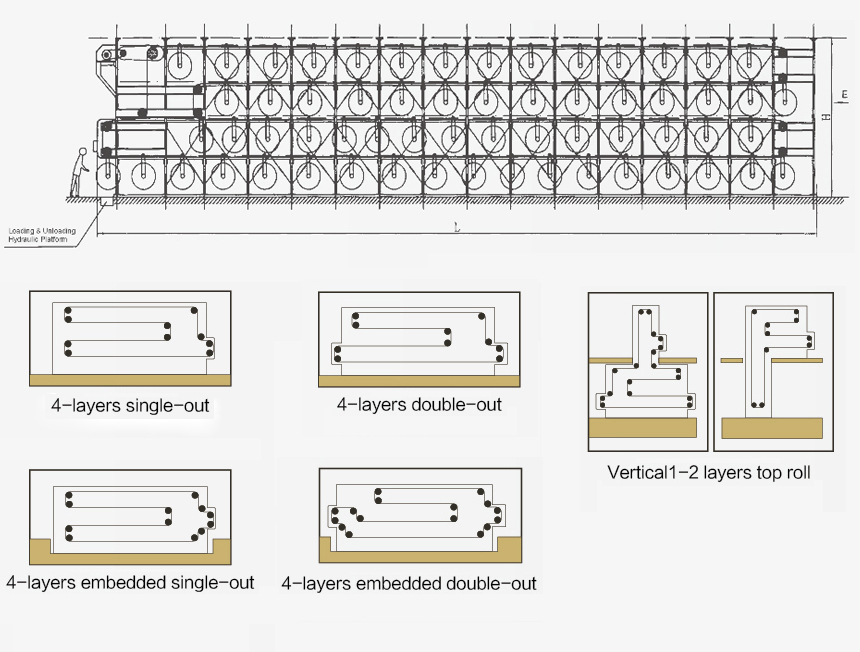

□ Our products can be selected from a variety of types, depending on the customer is application for workroom space. It not only can be installed on the ground, but also can be embedded under the ground. Our warehousing type beam stacker have many types including single exit, single exit digging type, double exit, double exit digging type, a two-story type to load from the second floor and unload from the first, and so on.

□ For each Store, we all installed a new control device which adopted film panel operating and liquid crystal screen. Furthermore, we also adopted technology of single microprocessor to work with the cycloidal gear speed reducer, so that it can automatic continuous running in both positive and negative direction or manual operating mode, then the operation system will select the shortest way and therefore automatic stop and starting up the beam stacker automatically.

□ Mode of Upper-beam: According to the request, you can select Hydraulic Platforms or Hydraulic Tip Transport Cart.

□ Storage Layer: Two, Four, Six Layers

□ Storage Capacity: 26~120pcs

□ Diameter of Warp Beam or Batched Roll: φ500~φ1500

□ Width of Warp Beam or Batched Roll: Model 150 ~ Model 390

□ On request of the customers it can be selective fitted with a computer control system. When it is on the upper-beam state, this system can be inputted the detailed information of the yarn related to the each beam saved into the computer When it is on the lower- beam state, it is understand fully at glance. In addition, the system will be automated running as long as you dick the computer for any specification the customer is required. This computer control, system also can connect to other computers to grasp of storaging data between each department, in order to achieve: production scheduling, planned circulating, to strengthen modern management mode and improved work efficiency.